Description

Please call if looking for this part ASAP as the website inventory may not be accurate during peak season.

[CLUTCH SET UP SHEET]

The Polaris SNYPR weight set was designed by Bikeman Performance for quick changes to clutching and maximum adjustability. No need to remove the Primary cover and spring to swap out the magnets. Simply pull the side panel off the sled and use the different length set screws or tungsten slugs to adjust RPM and belt pinch. These weights come with 3 adjustable holes in the side to add up to 12 magnets and a center hole at the heel for weight screws and slugs. Perfect for a turbo or N/A setup. These weights are perfect for that tuner looking to get the most out of their machine and make quick adjustments on the fly.

Additional Info:

- Designed for your Polaris sled

- Lets you dial in the weight from 58 to 90 grams

- SKU - 05-HAW-5889

- Comes with a set of magnets, 3 different size set screws, and tungsten slugs

Terminology:

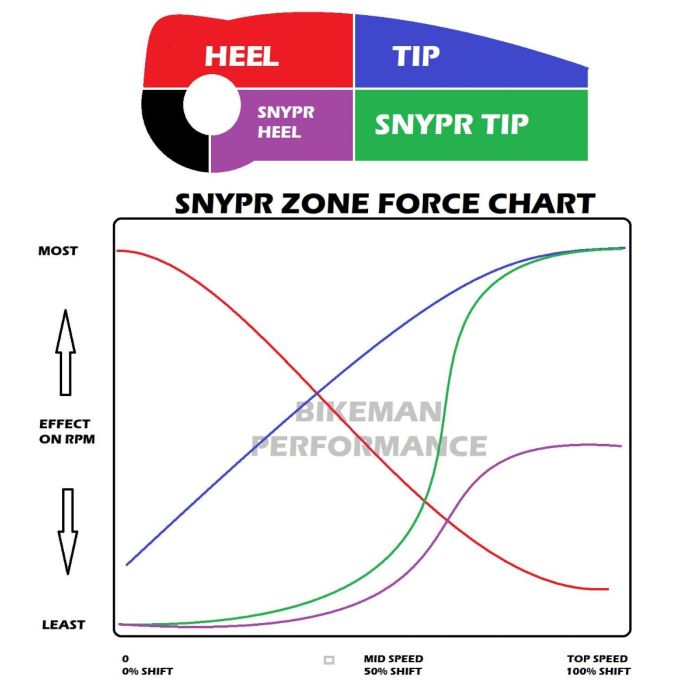

It is important to understand your Snypr weights and terminology. There are four quadrants within the Snypr weight. Each quadrant has a specific duty. The information below correlates with the images and shows each quadrant and shows how much effect each quadrant has as speed increases. At 0% shift your clutches are in the base position and the lowest gear. At 100%shift your clutches are fully shifted into the highest ratio, speed can increase above this point but only from rpm rising above the target peak hp.

IMAGE A -

-

THE HEEL - The heel weight force is applied instantly once the clutch weight overcomes the primary spring preload. It will gradually have less effect as you get closer to top speed.

- THE TIP - The tip weight force will gradually increase as speed is increased.

-

THE SNYPR HEEL - The Snyper heel weight will have little to no force until mid-way through the shift. After half shift, the force will come on fairly quickly but only be worth about half of the weight in the Snyper Tip.

- THE SNYPR TIP - The Snyper tip weight will have little to no force until mid-way through the shift. After half shift, the force will come on fast and have a similar effect as weight in the tip.

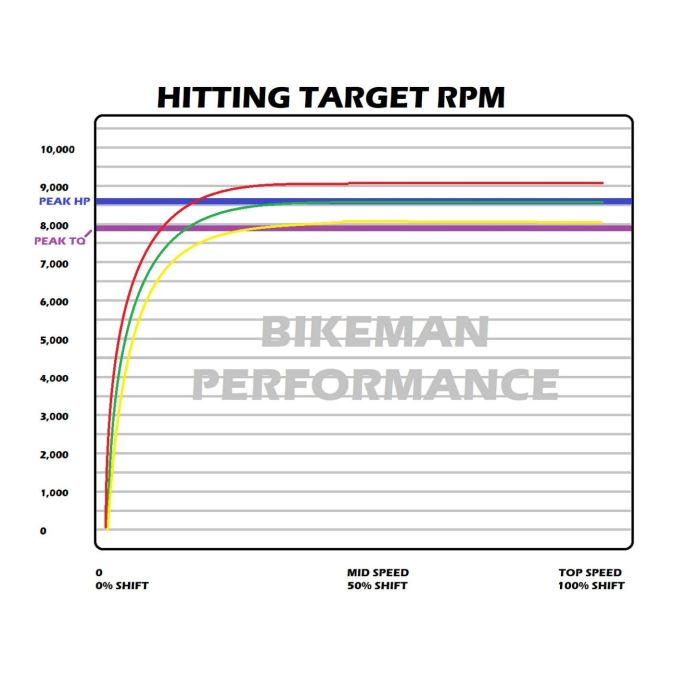

- HITTING YOUR TARGET RPM - Every engine has a peak horsepower and a peak torque. The graph shows a hypothetical peak hp and peak torque. The goal of your clutching is to get to peak torque very quickly and then have rpm rise to peak horsepower while loading the engine. This will achieve the quickest acceleration and the best feel. The RPM should stabilize at your peak horsepower rpm.

IMAGE B -

- GREEN LINE = IDEAL SHIFT - The Ideal shift will get to peak torque RPM very quickly then rise to peak horsepower RPM while loading the engine taking advantage of the torque while rising to peak power. Peak horsepower RPM should be hit by 30-40% through the shift. If your machine shifts like this you are set up perfectly.

- RED LINE = OVER TARGET RPM - Being over target RPM might feel responsive but will likely be much slower than an ideal shift. Over RPM is also harder on your engine. To bring your RPM down to the peak hp add weight centrally located between the heel and the tip.

- YELLOW LINE = UNDER TARGET RPM - Being under target RPM can feel lazy and unresponsive and will likely be much slower. Under-target RPM can also increase fuel efficiency and in some cases create less wear on engine components. To raise the RPM evenly across the shift remove some weight centrally located between the heel and the tip.

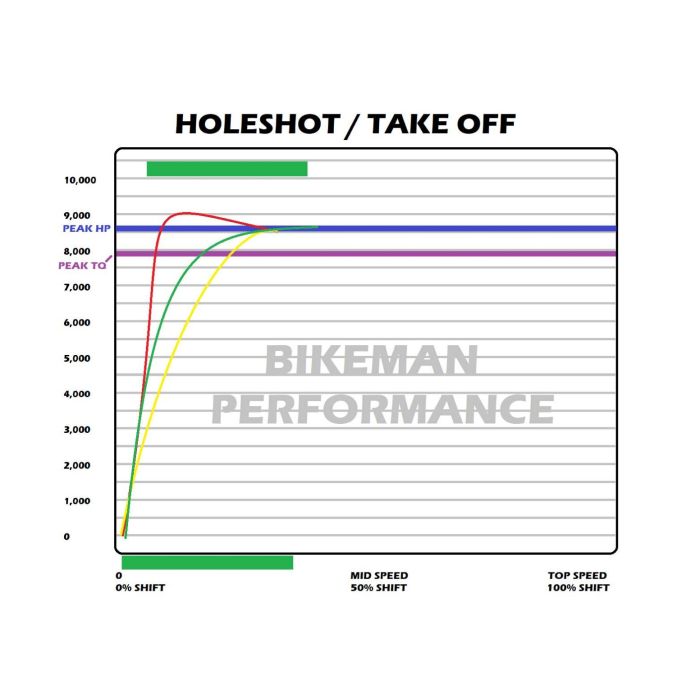

- TAKE OFF FROM STOP - The most belt slip and wear often occurs during the take off otherwise known as holeshot in the racing world. The take-off is the first 30-40% of the shift. In varying terrain conditions, the load on the belt during the section will drastically change due to resistance. Larger tires can also have a big impact on the take-off load. The chart shows different scenarios and a description of the scenarios and how to adjust your weights accordingly.

IMAGE C -

- GREEN LINE = IDEAL - No changes needed.

- RED LINE = OVERSHOOT - This condition needs to be addressed. Overshoot is caused by slippage or undershift during the first engagement of the clutch. This is easy to fix when using Snypr weights because they typically have extra weight in the heel section compared to non-Snypr weights and more mass potential. To fix this condition, add weight to the heel quadrant until it reacts like the green line.

- YELLOW LINE = UNDERSHOOT - This condition will feel lazy and lack responsiveness but is easy to fix when using the Snypr weights. An undershoot can also increase knock from RPM rising too slowly. To fix this condition, move some weight lower from the heel and tip into Snypr heel and tip evenly.

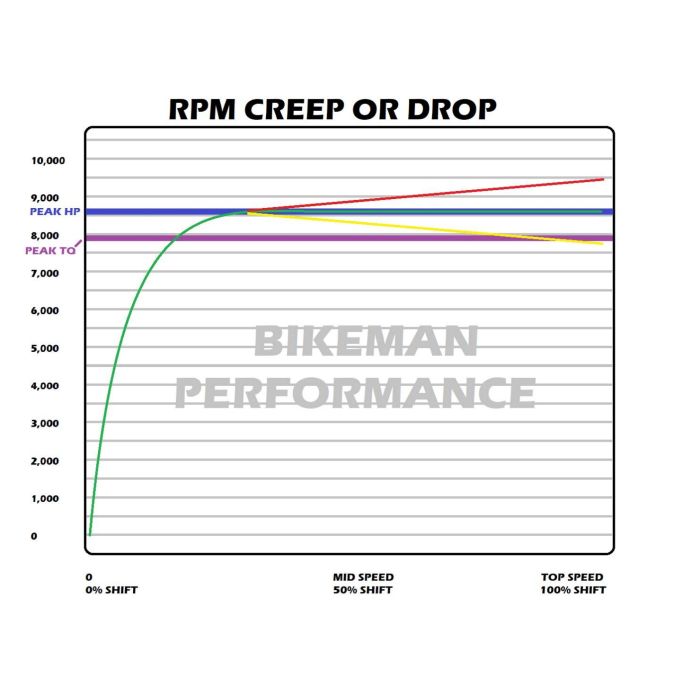

- RPM CREEP OR RPM DROP - RPM should remain fairly constant on 4-stroke applications and a slight creep/rise is okay on 2-strokes since the pipe is heating up and the RPM sweet spot moves slightly. You'll see the chart showing RPM creep and RPM drop, along with a description of what changes to make and control each situation.

IMAGE C -

- GREEN LINE = STEADY - No changes are needed, this is ideal.

- RED LINE = RPM CREEP - On a 2-stroke this is okay but usually not more than 100-200 RPM over peak horsepower. On a 4-stroke you want the RPM to be steady. If you have too much RPM creep you can tame it down by adding weight to Snypr tip or adding tip weight.

NOTE: Once clutches are fully shifted out the RPM will always rise 1 to 1 with MPH no matter what you do to your clutch weights. Make sure you are not trying to adjust your weights to adjust past full shift out. - YELLOW LINE = RPM DROP - RPM drop usually makes the vehicle respond but then fade off towards the top MPH. It can also increase engine knock due to pulling the motor down in RPM. It is an easy fix if you just remove some weight from the Snypr locations and if needed add a little to the heel and midway to the tip.

Need more info? Check out the video below!